Longtime Hallmark artist and Star Trek ornament pioneer, Lynn Norton, was kind enough to answer questions about his time at Hallmark and I am very pleased to pass along what he shared.

I would also like to recommend a 2015 Lynn Norton interview by Kevin Dilmore on StarTrek.com. It’s filled with fantastic behind-the-scenes insights into Norton’s ornament development, which I deliberately avoided covering again: “Hallmark Sculptor Lynn Norton on the Storied History of Trek Keepsake Ornaments”.

HallmarkStarTrekOrnaments.com: What is Lynn Norton doing nowadays and how is he scratching his artistic itch?

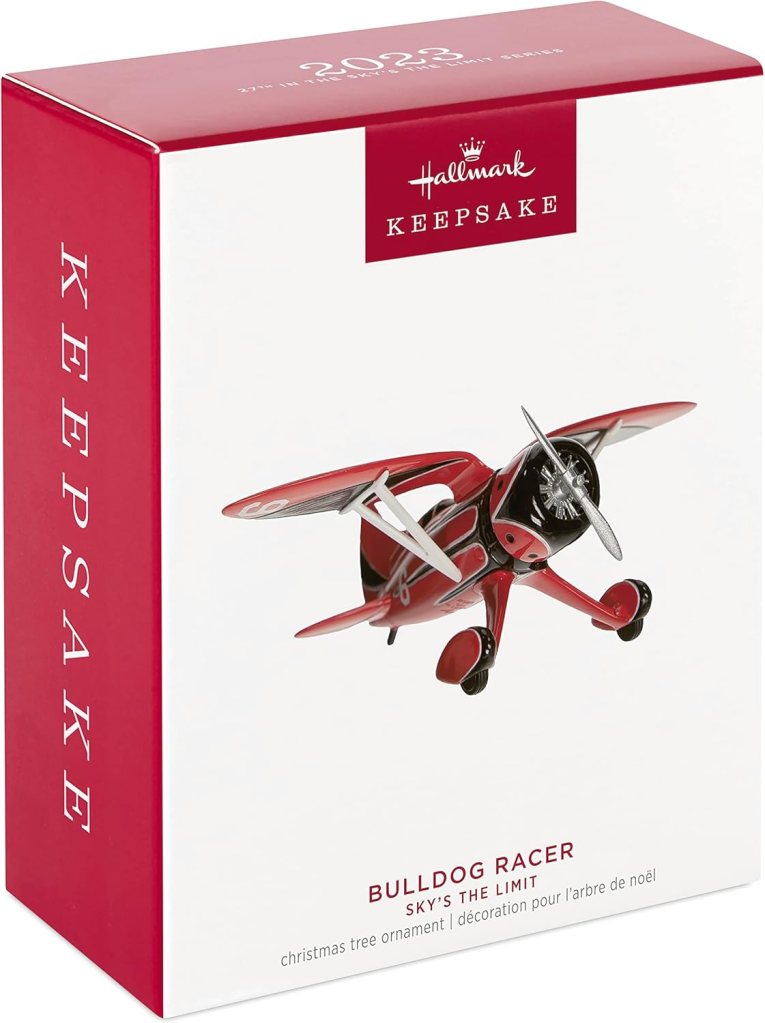

Lynn Norton: I’m still sculpting original patterns for new products from my home-based studio, one contract at a time. In October 2025, I submitted an original sculpture/prototype for a 2027 Hallmark ornament in the “Sky’s the Limit” vintage airplane series. I’ve sculpted all of the airplane ornaments and hope to continue.

I began my Hallmark career on July 5th, 1966, which is also the year I graduated H.S. and began watching STAR TREK on TV. My original employment was to be trained as an Engraver, which is what I did for the next 20 years.

The only other creative endeavor I’ve pursued recently is writing free-verse poetry. My wife, Tina Hacker, is an accomplished poet and encouraged me to start writing during the pandemic. No one was more surprised than I when some of my musings were published.

HSTO: How did you first become involved in designing Star Trek ship ornaments for Hallmark?

Norton: Dumb luck. I was the right person in the right place at the right time. Paramount had invited Hallmark to produce a variety of licensed products to commemorate the upcoming (1991) 25th anniversary of the STAR TREK television series. Artists and directors from greeting cards, party goods and ornaments were asked to develop concepts. Keepsake Ornament designs in that era were mostly seasonal, traditional and whimsical. Concepts submitted for a STAR TREK ornament were no exception. You’ve, no doubt, heard about drawings depicting a cartoonish Enterprise, pointy eared Santa popping out of a hinged bridge dome with garland draped around the saucer.

I was reviewing concepts for the ornament-development-team and the drawings totally freaked me out. I joined forces with editorial director, Tina Hacker in an attempt to convince management that a more realistic design would be better received by fans and collectors. We won the argument and the rest is history. Tina and I were married in 1997 and displayed the Enterprise ornament on our wedding cake as a symbol of our first collaboration and celebration of our next.

I was assigned to sculpt the Enterprise ornament because of my skills as an engraver and model maker. Artists in the sculpting studio were mostly familiar with manipulating soft materials (clay, wax, fabric) to develop three-dimensional patterns. Numerous former engravers had also joined the studio and we were adding industrial skills and materials to the mix. Our capabilities made finely detailed designs more accessible and increased the range of ornament possibilities.

The 1991 Enterprise ornament was my first project. I created the original pattern with aluminum-filled epoxy resin, styrene and metal. Rigid materials were perfect for leveraging my engraving skills to produce fine details. Apologies for deeply engraved grid lines on the saucer. Franklin Mint had produced a pewter version of the Enterprise which featured extremely exaggerated details. I was encouraged to sculpt the Hallmark ornament in a similar manner. Due to the successful first ornament, exaggerated detail lines became an expectation on future STAR TREK ship designs. I wasn’t able to convince them otherwise until the 40th anniversary edition in 2006 which, ironically, is the year I retired from Hallmark.

HSTO: Why were you not involved with the ’92 Galileo yet returned the following year?

Norton: I had surgery to repair a damaged tendon in my dominant arm three weeks before the original sculpture was due. Fellow artist Dillard Rhodus graciously took my assignment in addition to his already heavy workload. I was significantly involved with planning and developing the Galileo ornament but resumption of sculpting had to wait until the following year. Note: Dillard Rhodus was also an engraver whom I’d worked with for many years prior to joining the sculpting studio. He had a lengthy career sculpting numerous Keepsake and STAR WARS ornaments.

HSTO: What was it about STAR TREK that made it such a long-running part of your career?

Norton: Frankly, it was probably due to the phenomenal retail success of the first STAR TREK ornament and repeated success in following years. I suppose, Hallmark and the licensor considered my participation to be an essential ingredient. Participation in planning sessions and conference-calls with the licensor became a regular part of my job. Imagine how exciting that was because I’m also a FAN.

HSTO: What did the design process typically look like from concept to finished ornament?

Norton: At times, this may look like “sausage making” but keep in mind that ornaments are commercial art. Every aspect of development and distribution has a price tag, including esthetic decisions made during sculpting. I’m extremely flattered to be credited for creating ornaments, but I didn’t do it alone. Dozens of anonymous Hallmark professionals contributed their unique talents to each project.

Hallmark renewed licensing agreements annually. STAR TREK starship ornaments required about 18 months to comfortably get from concept to retail stores due to their complexity, production tooling, electrical components and testing. Each year, artists and directors submitted multiple ornament concepts to the licensor for review, which included cost projections and retail expectations. The licensor, in turn, presented their own ideas depending on which starships were most popular from TV series, feature films and promotions for significant milestones. Negotiations commenced and agreements were made.

Once an ornament concept was selected, scheduling began for each stage of development. When I was given a sculpting assignment, the licensor provided me with behind-the-scenes information, drawings and photographs. While studying these resources, it was not uncommon to discover inconsistencies. Physical and digital models were often modified at-the-last-minute prior to filming, so it was important to validate images that actually ended up on TV or big screens. I also examined competitors’ products to see what they got right and what they got wrong.

Before starting each project, I consulted with a product-development-engineer to determine a cost-effective strategy for manufacturing, decorating and packaging. Providing enough space for internal electrical components was always challenging. My preliminary drawings were esthetically adjusted to satisfy all requirements and reviewed by art directors. Sculpting and prototyping commenced.

My first sculpting task was to render all of the basic component shapes and get approval to proceed from Hallmark and the licensor. Once that was accomplished, surface details were added and the finished sculpture submitted for review. The approved sculpture was then disassembled and sent to a molding facility to develop RTV rubber molds and resin duplicates. The first set of molded duplicates were used to create a fully decorated/assembled prototype. The prototype was then reviewed by Hallmark and the licensor. (It was extremely important that prototypes were visually accurate. They often got photographed for catalogs, retail boxes, publications and promotional materials before actual product was available). Final approval by the licensor set production development in motion. More duplicates were molded and painted to be identical to the original prototype. Drawings and technical notes were generated to inform mold-makers and manufacturers. Comprehensive packages were assembled and offered to potential vendors to bid on manufacturing. The approved ornament design was then placed with a vendor and scheduled for manufacturing. My work was done until samples of the finished product were submitted to Hallmark and the licensor for review. In mid-July, the buying frenzy began at Hallmark stores. Artists were scheduled for appearances and ornament signing events at retail stores and conventions. Phew!

HSTO: How much time did you have to work on the ’91 Enterprise?

Norton: As I recall, about 75 hours. The original Enterprise design incorporated geometric shapes. I was able to fabricate most of its features with a miniature lathe and milling machine. Surface details were rendered with hand-tools.

HSTO: How closely did you work from studio references versus on-screen footage?

Norton: In most cases, STAR TREK ships were only viewed by the general public on TVs and in feature films. My intent was to create ornaments that appeared the same as ones seen on screen. Resources from the licensor were invaluable. Blueprints and documentation of filming-models (physical and digital) helped me determine shapes and details that weren’t apparent in screen-shots. Publications and other consumer products were also useful as references, but some were dubious. Nothing could compare with source material(s).

HSTO: What were the biggest challenges in translating a full-size starship into an ornament-scale design?

Norton: Deciding what details to keep and what to leave out. I’ve always respected artists that could define “character” in drawings with single lines without the benefits of shadow and color. I took my cues from them.

HSTO: How much freedom did you have creatively, and where were you most restrained?

Norton: The only creative freedom I exercised was choosing colors for the finished product(s). Even that prompted negotiations with art-directors. The licensor would often send color-chips of paint used on physical filming models. The colors were very dull, flat and grey. When illuminated with bright lights on a stark, black background they took on completely different characteristics. If we (Hallmark) had applied those colors to STAR TREK ship ornaments, they would have looked like something dug up in the garden. Model makers know that the smaller the scale, the more white pigment needs to be added to achieve scale-accurate colors (there’s even a formula). Finally, I had to select colors that were attractive in retail displays as well as hiding under a tree branch. All in a day’s work.

HSTO: STAR TREK fans are famously detail-oriented—how did that influence your design decisions?

Norton: I am a fan; thrilled to have been in a position to create STAR TREK products that I would be proud to own, display and share with other fans.

HSTO: Were there ever details you wanted to include but couldn’t due to size, cost or engineering constraints?

Norton: Often. A recent example was the 2016 anniversary-edition Enterprise ornament. The concept was planned to be decorated with a mirror-bright gold finish called vacuum-metalizing (a.k.a.vacuum-plating) but the process is very expensive and problematic in production due to spoilage. Easily, 10% or more of produced items have to be discarded due to imperfections. In addition, not all manufacturers have the capability. If awarded the manufacturing contract, some vendors would have to sub-contract the decoration process. My creative director was uncertain if the bright gold finish would be possible (or affordable) and encouraged me to choose gold-metallic paint as an alternative. The ornament prototype was painted with gold-metallic paint and photographed for retail boxes, catalogs and promotional publications. No one was more surprised than I when mirror-bright Enterprise ornaments were unveiled at Ornament Premiere in Hallmark stores.

Look for Talking Keepsakes: Lynn Norton Reflects on a Hallmark Career – Part 2 next week.

Pingback: Archive | Hallmark Star Trek Ornaments

Pingback: Talking Keepsakes: Lynn Norton Reflects on a Hallmark Career – Part 2 | Hallmark Star Trek Ornaments